Unfortunately the legacy corner mitering and inability for inventor to integrate overlapping flange treatments leaves something to be desired.

Inventor sheet metal partial flange.

Total project time approximately 20 minutes.

You can override the default sheet metal.

Create a 2d open profile sketch.

Inventor sheet metal is now a more capable tool in inventor with the addition of multi body modeling.

Click an open profile.

The geometry for each end is in the attached file was draw in auto cad and imported into inventor.

Create a contour flange.

To add a flange feature you select one or more edges and specify the size and position of the material added.

A flange feature consists of a face and bend connected to an existing face along a straight edge.

Create sheet metal flange with specified width create a flange in sheet metal and specify the width of the flange.

If there are two or more solid bodies in the part file click the solids selector to choose the participating solid body.

Add flanges to the bracket 4 40 completing the project.

To add a flange feature you select one or more edges and specify the size and position of the material added.

Optional if a body exists click new solid to create a new body.

On the ribbon click sheet metal tab create panel contour flange.

Create sheet metal flange with offset width create a flange and define its width as an offset.

Create 3 bend corner on flange in sheet metal.

About flanges in sheet metal a flange feature consists of a face and bend connected to an existing face along a straight edge.

In this tutorial video we will learn sketch sh.

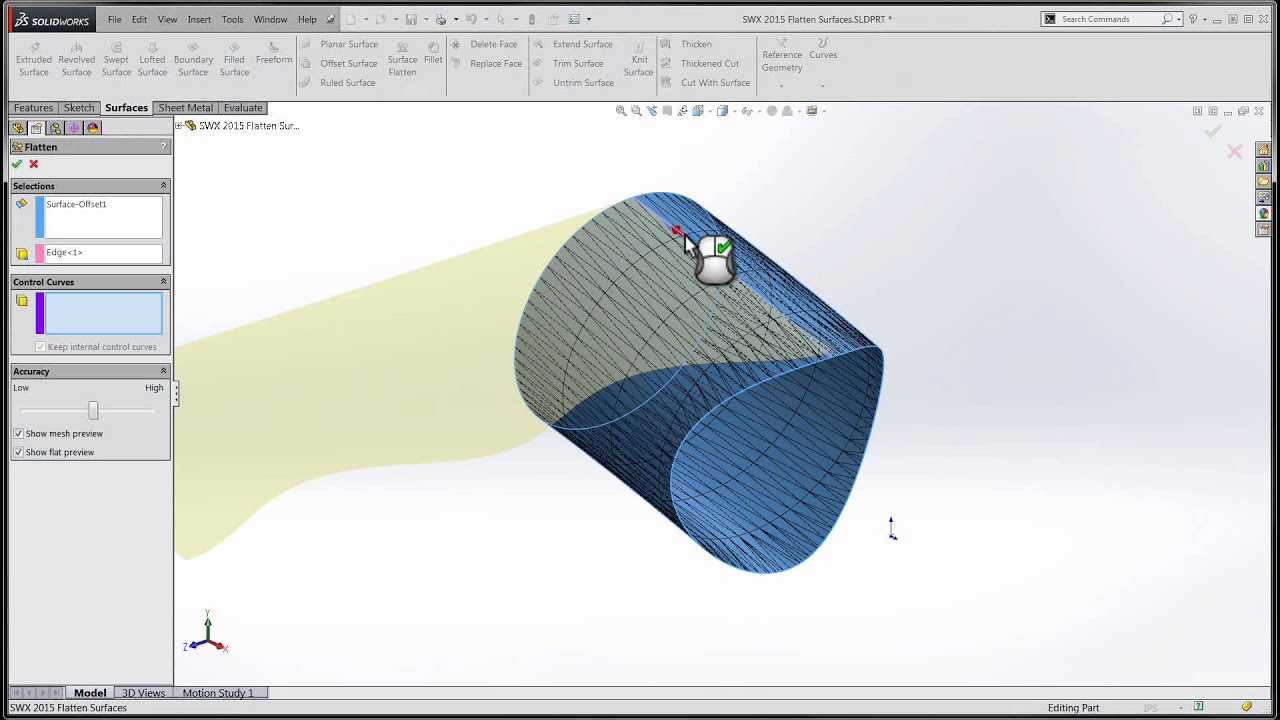

Sheet metal lofted flange open profile.

Corners that generate during the creation of flange and contour flange features display the default corner relief shape when the model is flat.

Design a sheet metal bracket in this project we ll design a bracket using the sheet metal environment inside inventor for an inkjet printer while in context of the larger assembly.