When storing gasoline a standard fixed roof tank of 120 feet 36 7 meter in diameter can lose 750 000 worth of valuable product annually and cause 1 3 million pounds of pollution.

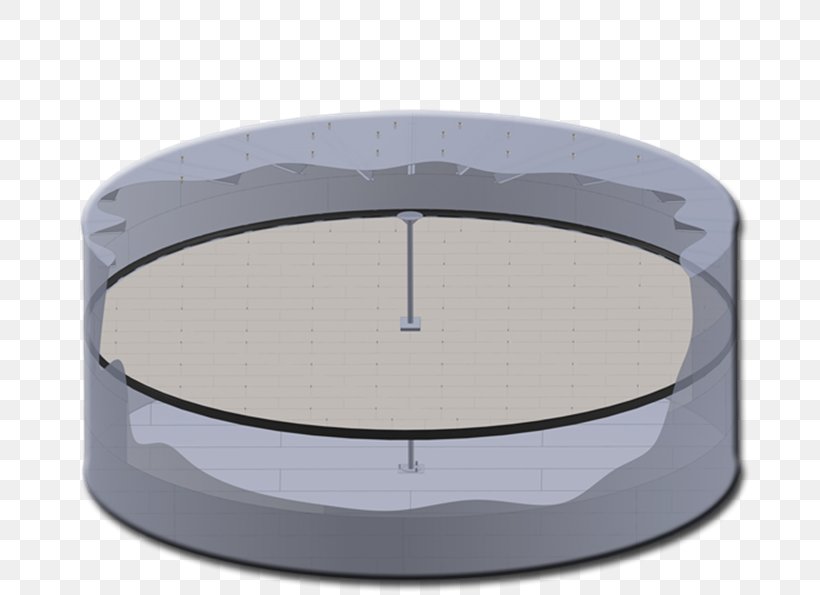

Internal floating roof tank vent.

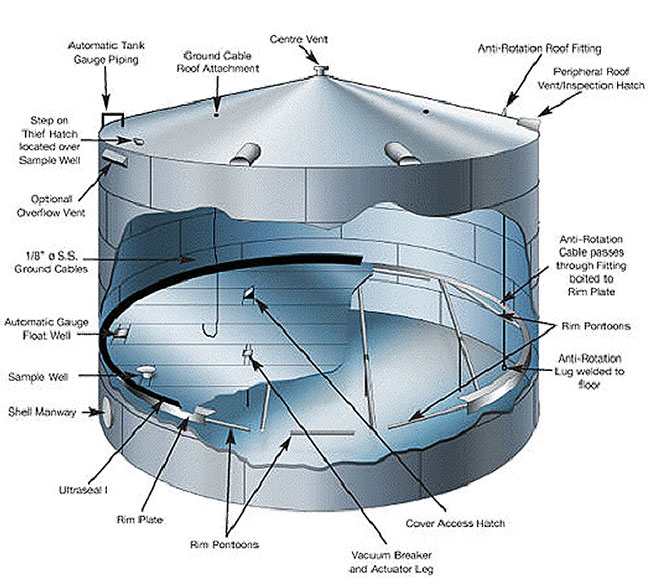

The vents in the floating roof protect the roof and rim seal and accommodate liquid movement and thermal breathing.

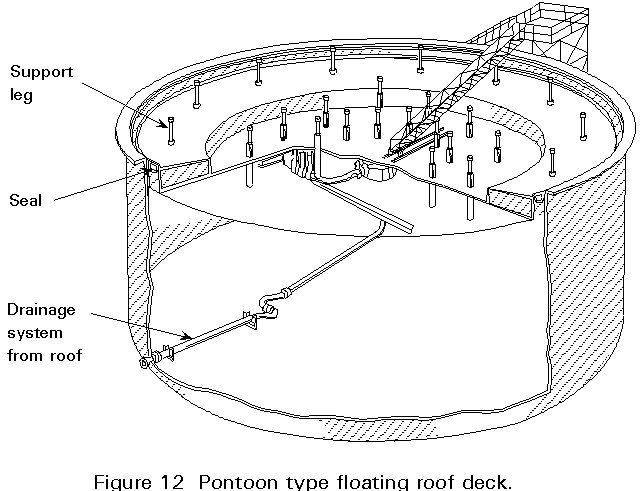

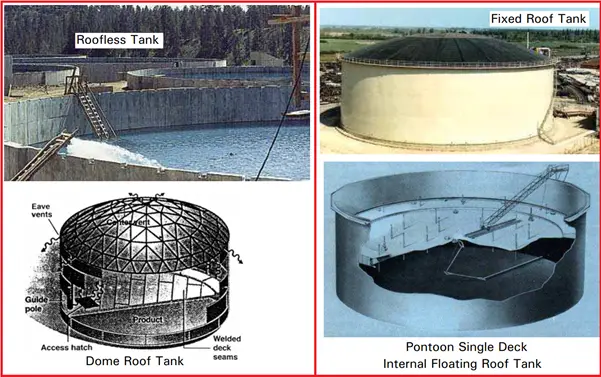

Cover vented to a control device pressure tank fixed roof tank with internal floating roof tank tank equipped with an external floating roof tank inside an enclosure which is vented to an enclosed combustion device the internal floating roof in a fixed roof tank with ifr design must float on the liquid surface except when the floating roof must be supported by the leg supports.

In case of fire the seal material on the floating roof would melt and likely provide sufficient venting.

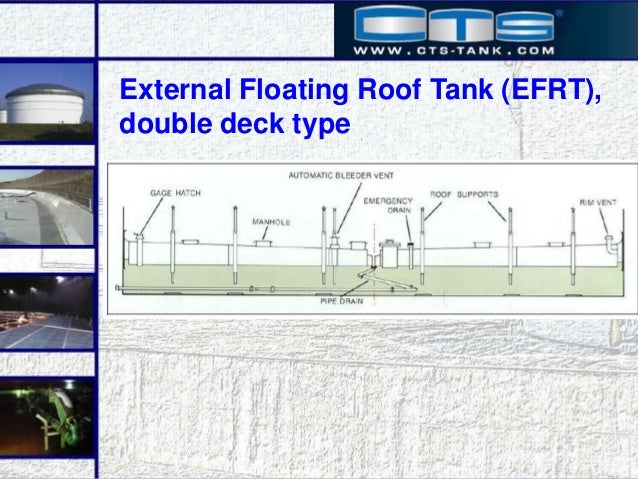

For normal venting api 650 g 8 3 and h 6 2 specifies vents in the fixed roof tank shell and internal floating roof.

Allentech is a privately held manufacturer and erector of internal floating roofs and perimeter seal systems for above ground storage tanks and covers for api separator basins.

Emergency venting is not specified for either the fixed roof shell or internal floating roof.

Adopting the internal floating roof cover in the liquid surface is recognized as the most ideal economic and practical method to reduce the evaporation loss of oil products.

Openings through the deck of the floating roof shall be equipped as described in paragraphs a 2 i through a 2 viii of this section.

Ultraflote internal floating covers prevent evaporation of volatile petroleum liquids and can pay for themselves in less than six months.

52 the five different options are as follows.

Operating since 1986 allentech is recognized worldwide within the petrochemical industry as the premier supplier of these custom roofs and accessories serving major.

Instead the cfrt is equipped with a pressure vacuum pv vent and may even include a gas blanketing system such as that used with fixed roof tanks these tanks are designed as in appendix c of the api standard 650.

I each opening except those for automatic bleeder vents vacuum breaker vents and rim space vents shall have its lower edge below the surface of the stored liquid.

The vents can be no more than 32 feet apart and must provide a total open area of at least 0 2 square foot per foot of tank diameter.